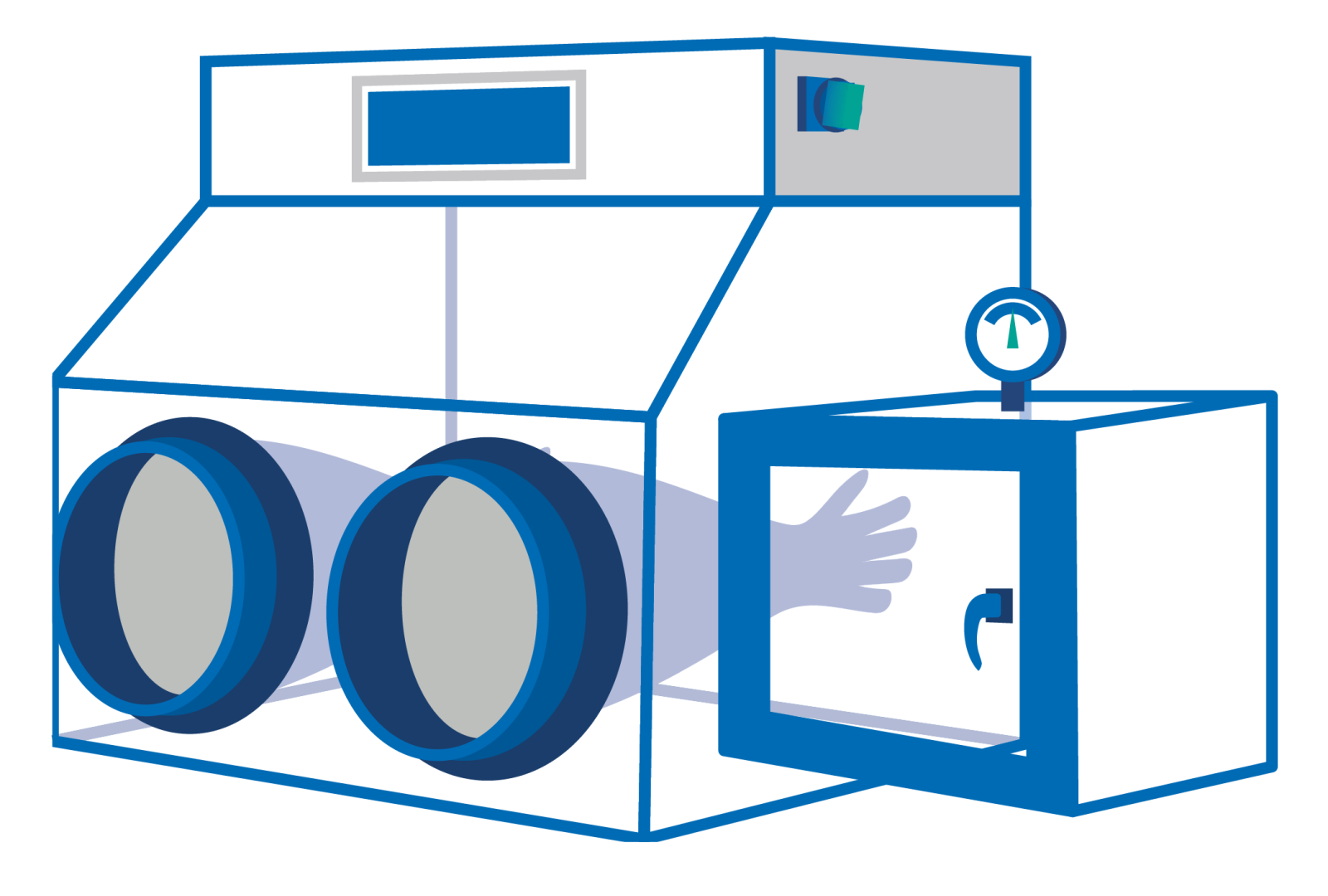

Gloveboxes play a vital role in protecting products from human or environmental contamination as well as protecting individuals and environments from workplace hazards.

They’re designed to provide a controlled, enclosed work environment that is separated from workers by a barrier, ensuring the containment of these sensitive and critical materials.

Every worker has the right to a safe workplace. When manufacturing specialized products in a pharmaceutical manufacturing environment, there are very specific requirements for hand protection. Production and handling of these types of products typically happens in a clean or controlled environment and quite often in a sterile environment as well.

Due to the propensity of sensitive materials utilized in the life sciences, two main types of gloveboxes may be used; each is designed for the specific hazards present or the level of cleanliness required.

| Containment Gloveboxes Are designed to protect the operator and ambient environment from the material being processed. They are commonly found in pharmaceutical applications relating to the development of oral treatments, neurological pain drugs, enhancing drugs, nuclear medicine, and other potent drugs. |

| Isolation Gloveboxes

Protect the material being processed from the operator and/or the environment. Isolation gloveboxes are used in applications such

as aseptic drug manufacture and filling and the development of parenteral (injectable) drugs. |

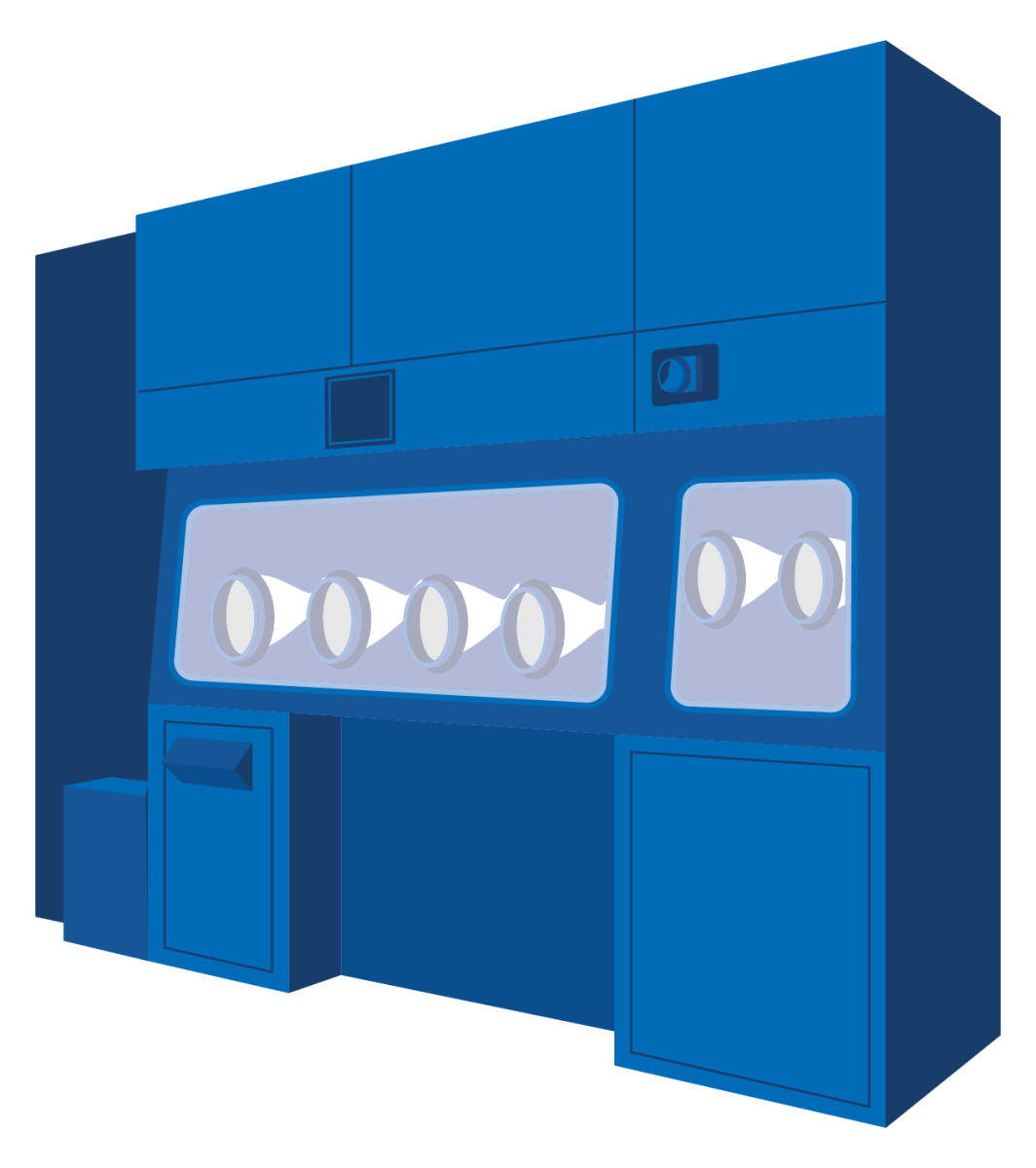

| Isolators

Combine features of containment and isolation glove boxes. Isolators are used in the manufacture of cytotoxic parenteral drugs, some chemotherapy drugs, and biopharmaceutical cancer drugs. |

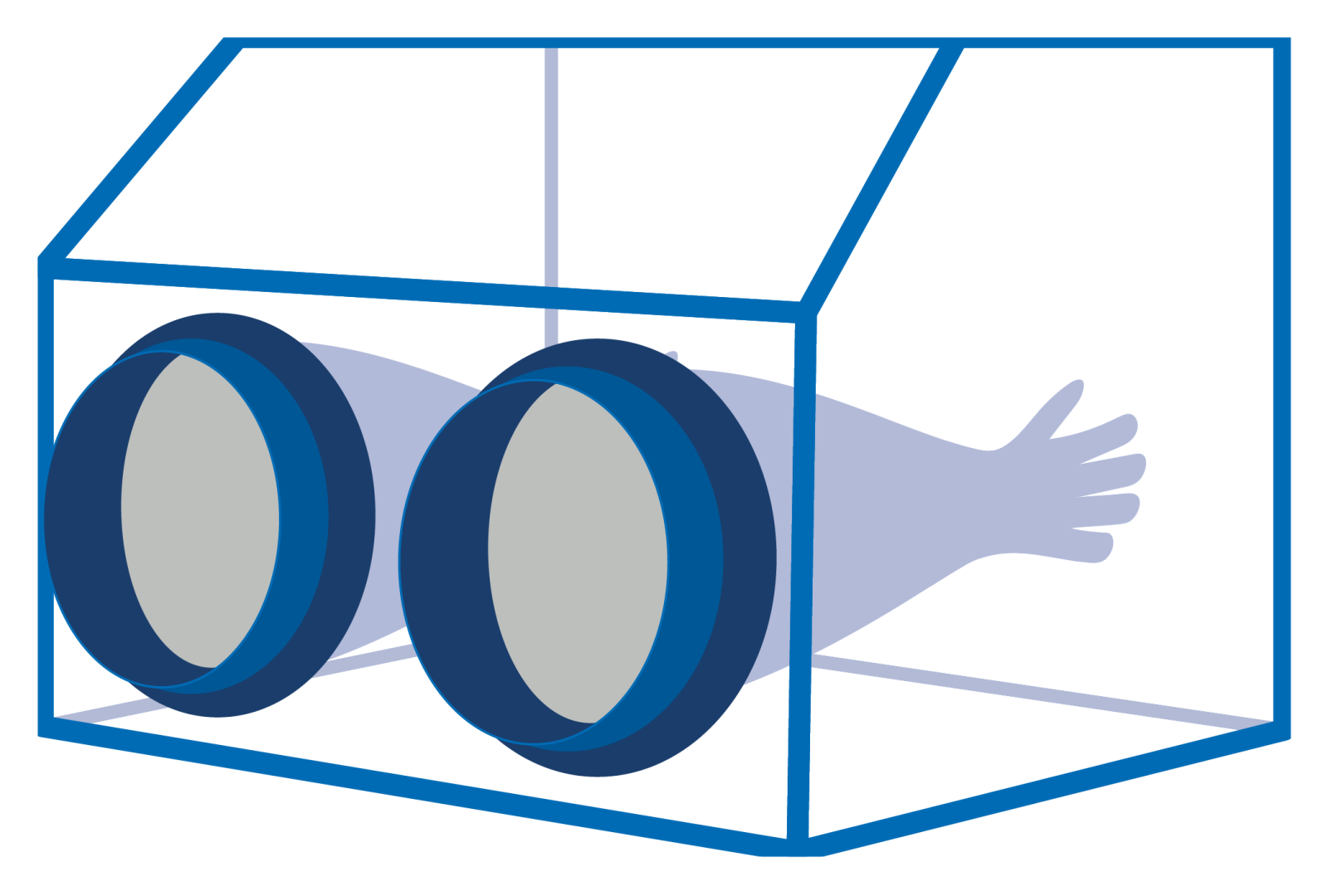

The gloves used inside a glovebox provides the vital interface between the worker and the interior glovebox environment and must maintain a clean, reliable barrier while allowing the worker to effectively conduct manual tasks.1 The gloves’

integrity is crucial, as any breach in containment puts workers and/or products at risk of contamination.

While glovebox gloves have traditionally been manufactured of natural rubber latex and CSM, recent advances in materials such as nitrile offer significantly improved protection, reliability, and longevity.

NITRILE

Nitrile is a synthetic, non-solvent-based, FDA-approved polymer with excellent anti-static properties and is ideal for use with solvents and powders. Nitrile can withstand temperatures of up to 120°C and is autoclave compatible. It can also be sterilized by Gamma Irradiation and sanitized with Vaporized Hydrogen Peroxide (VHP) and Isopropyl Alcohol (IPA). Nitrile gloves can also be washed, processed, and packaged within a cleanroom environment, ensuring the gloves are an ultra-low contamination risk before being introduced into the isolator glove box.

Nitrile has superior puncture resistance, dexterity, and user comfort and offers excellent chemical resistance providing extended permeation protection against many cytotoxins and the ability to maintain its properties even after gamma irradiation.

BIOCLEAN™ RABS AND ISOLATOR GLOVES

BioClean™ RABS and Isolator Gloves are manufactured from nitrile with incredibly low levels of particles and excellent ESD properties which offers both safety to the worker and the products they are handling. The gloves are made with accelerator-free biodegradable nitrile, and individually triple-bagged in easy-open PE for convenient access.

BioClean™ gloves are 100% inspected and water leak tested and can be Gamma irradiated with a Sterility Assurance Level of 10-6. They meet ASTM D6978-05 standards for handling chemotherapy drugs and offer excellent resistance to VHP and IPA.

At Ansell, we are committed to delivering cutting-edge protection, enabling workers to increase quality and productivity without putting their health at risk. BioClean™ Nitrile Isolator gloves are an excellent choice for workers with improved comfort, protection, and performance.

View all Ansell has to offer here